Multiple Choice

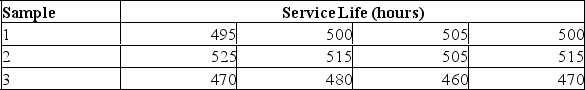

A design engineer wants to construct a sample mean chart for controlling the service life of one of the types of light bulbs his company produces.He knows from numerous previous samples that this service life is normally distributed with a mean of 500 hours and a standard deviation of 20 hours.On three recent production batches,he tested service life on random samples of four bulbs,with these results:  What is the sample mean service life for sample 2?

What is the sample mean service life for sample 2?

A) 470 hours

B) 495 hours

C) 500 hours

D) 515 hours

E) 525 hours

Correct Answer:

Verified

Correct Answer:

Verified

Q61: A point that plots below the lower

Q62: The six sigma quality improvement methodology is

Q63: The optimum level of inspection occurs when

Q64: Concluding that a process has not changed

Q65: As the sample size increases,the distribution of

Q67: The process capability index,indicated by Cp is

Q68: The sampling distribution of sample means taken

Q70: The number of defective parts in a

Q71: The specification limits for a product are

Q112: A control chart used to monitor the