Essay

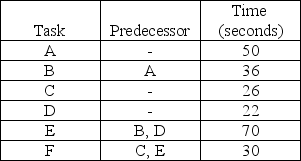

A company is designing a product layout for a new product. It plans to use this production line eight hours a day in order to meet a schedule of 400 units per day. The tasks necessary to produce this product are detailed in the table below.

a. Draw the network described in the table.

a. Draw the network described in the table.

b. Without regard to a production schedule, what is the minimum possible cycle time (in seconds) for this situation; what is the maximum?

c. What is the required cycle time (in seconds) in order to meet the schedule?

d. What is the theoretical minimum number of workstations needed to meet the schedule?

e. Balance this line using longest processing time.

f. What is the efficiency of the balance obtained in part e?

Correct Answer:

Verified

The network diagram appears below. Minim...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q19: In assembly-line balancing,the theoretical minimum number of

Q65: The typical goal used when developing a

Q115: A product requires 24 separate tasks, and

Q117: Slotting fees<br>A) are charged by retailers to

Q134: Solving a load-distance problem for a process-oriented

Q137: A production line is to be designed

Q139: Which of the following layouts generally has

Q146: The layout strategy that deals with <b>low-volume,

Q153: _ is the use of computer software

Q224: A process-oriented layout is the traditional way