Essay

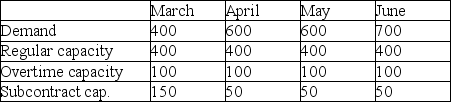

Byron's Manufacturing makes tables. Demand for the next four months and capacities of the plant are shown in the table below. Unit cost on regular time is $40. Overtime cost is 150% of regular time cost. Subcontracting is available in substantial quantity at $75 per unit. Holding costs are $5 per table per month; back orders cost the firm $10 per unit per month. Byron's management believes that the transportation algorithm can be used to optimize this scheduling problem. The firm has 50 units of beginning inventory and anticipates no ending inventory.

a. How many units will be produced on regular time in June?

a. How many units will be produced on regular time in June?

b. How many units will be produced by subcontracting over the four-month period?

c. What will be the inventory at the end of April?

d. What will be total production from all sources in April?

e. What will be the total cost of the optimum solution?

f. Does the firm utilize the expensive options of subcontracting and back ordering? When; why?

Correct Answer:

Verified

(a) 400; (b) 250; (c) 0; (d) 550; (e) To...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q9: _ is the process of breaking the

Q23: The aggregate planning process usually includes expediting

Q42: Disaggregation:<br>A) breaks the aggregate plan into greater

Q62: In aggregate planning, one of the adjustable

Q62: Dependence on an external source of supply

Q72: Identify (a) the demand options for aggregate

Q76: _ is a capacity option that works

Q96: Planning tasks associated with loading, sequencing, expediting,

Q110: In level scheduling, what is kept uniform

Q119: Normally, the transportation model is used to