Essay

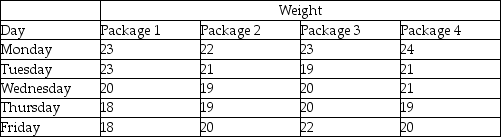

A quality analyst wants to construct a sample mean chart for controlling a packaging process.He knows from past experience that the process standard deviation is two ounces.Each day last week,he randomly selected four packages and weighed each.The data from that activity appear below.

(a)Calculate all sample means and the mean of all sample means.

(a)Calculate all sample means and the mean of all sample means.

(b)Calculate upper and lower 2-sigma x-bar chart control limits that allow for natural variations.

(c)Based on the x-bar chart,is this process in control?

Correct Answer:

Verified

(a)The five sample means are 23,21,20,19...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q4: The term _ is used to describe

Q8: A hospital-billing auditor has been inspecting patient

Q45: What are the three possible results (or

Q48: Acceptance sampling:<br>A)may involve inspectors taking random samples

Q50: Consumer's risk is the probability of:<br>A)accepting a

Q73: Acceptance sampling accepts or rejects an entire

Q110: Why do range charts exist? Aren't x-bar

Q128: An operating characteristic (OC)curve describes:<br>A)how many defects

Q227: According to the text, what is the

Q237: An operating characteristics curve shows:<br>A) upper and