Essay

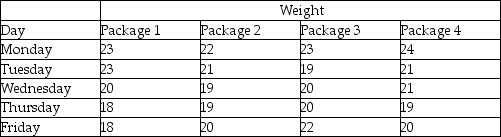

A quality analyst wants to construct a sample mean chart for controlling a packaging process.He knows from past experience that when the process is operating as intended,packaging weight is normally distributed with a mean of twenty ounces,and a process standard deviation of two ounces.Each day last week,he randomly selected four packages and weighed each.The data from that activity appear below.

(a)If he sets an upper control limit of 21 and a lower control limit of 19 around the target value of twenty ounces,the control chart is based on what value of z?

(a)If he sets an upper control limit of 21 and a lower control limit of 19 around the target value of twenty ounces,the control chart is based on what value of z?

(b)With the UCL and LCL of part a,what do you conclude about this process-is it in control?

Correct Answer:

Verified

(a)These control limits are one standard...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q11: The C<sub>pk</sub> index measures the difference between

Q23: The probability of rejecting a good lot

Q87: In statistical process control,the range is often

Q87: A nationwide parcel delivery service keeps track

Q91: McDaniel Shipyards wants to develop a control

Q119: Some degree of variability is present in

Q121: Averages of small samples,not individual measurements,are generally

Q230: An x-bar control chart was examined and

Q231: The _ is the percentage defective in

Q257: Briefly explain what the Central Limit Theorem