Essay

JIT Accounting

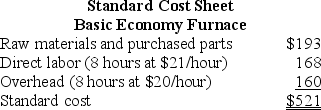

Warm Glo manufactures gas furnaces for residential use. It uses a standard cost system that isolates all variances at purchase so that all product costs are stated at standard cost. All variances are included as part of cost of goods sold. Overhead is allocated based on direct labor hours. Standard cost for the basic economy model furnace follows.

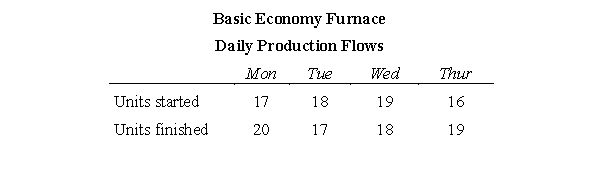

Warm Glo manufactures the basic economy furnace in a dedicated flow line using just-in-time production principles. All raw materials and purchased parts needed to assemble a complete furnace are delivered to the plant by 8:00 am of the day the furnace begins production. While each furnace requires eight direct labor hours, total throughput time for each furnace is two working days (16 hours). The difference between total throughput time and the eight direct labor hours is waiting time. Furnaces that are started in production one day are finished the next day. Four hours of direct labor are used the first day and four hours of direct labor are worked the second day. All production for the week is accumulated and shipped out to the distributor by train on Saturday.

Warm Glo manufactures the basic economy furnace in a dedicated flow line using just-in-time production principles. All raw materials and purchased parts needed to assemble a complete furnace are delivered to the plant by 8:00 am of the day the furnace begins production. While each furnace requires eight direct labor hours, total throughput time for each furnace is two working days (16 hours). The difference between total throughput time and the eight direct labor hours is waiting time. Furnaces that are started in production one day are finished the next day. Four hours of direct labor are used the first day and four hours of direct labor are worked the second day. All production for the week is accumulated and shipped out to the distributor by train on Saturday.

Warm Glo maintains a finished-goods inventory account for basic economy furnaces that reflects the standard cost of furnaces not yet shipped out. Warm Glo uses a raw and in-process materials account (RIP) and JIT backflushing accounting. All accounts are updated at the end of each day for all production and transactions occurring that day. Conversion costs are charged directly to the finished goods inventory account as work is performed on furnaces. Through the end of Thursday of the current week the following table contains information about the plant's production of basic economy furnaces:  Required:

Required:

a. What is the balance in the RIP account for the basic economy model at the end of Thursday?

b. What is the balance in the finished goods account (basic economy model) at the end of Thursday?

Correct Answer:

Verified

JIT Accounting

This problem requires an...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

This problem requires an...

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q1: The maintenance department's costs are allocated to

Q2: JIT and the Role of Accounting<br>The president

Q4: Responsibility Centers<br>The Maple Way Golf Course is

Q13: Describe how budgets and budgeting systems help

Q19: The Fancy Umbrella Company makes beach umbrellas.

Q24: The Alphonse Company allocates fixed overhead costs

Q53: ABC and Average Cost in a Service

Q56: Budgeting Direct Materials<br>The Jung Corporation's budget calls

Q61: Accounting for JIT<br>Vail operates a JIT plant

Q62: Choosing Allocation Bases For Levying Taxes<br>The town