Short Answer

TABLE 17-4

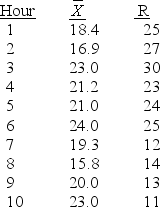

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

-Referring to Table 17-4, what is the value of d2 factor?

Correct Answer:

Verified

Correct Answer:

Verified

Q19: A process capability is estimated by the

Q36: The cause of variation that can be

Q46: Once the control limits are set for

Q51: The C<sub>p</sub> index measures the potential of

Q51: TABLE 17-7<br>A supplier of silicone sheets for

Q55: TABLE 17-7<br>A supplier of silicone sheets for

Q56: TABLE 17-8<br>Recently, a university switched to a

Q58: TABLE 17-9<br>The manufacturer of cat food constructed

Q82: The smaller the capability index, the more

Q126: TABLE 17-5<br>A manufacturer of computer disks took