Multiple Choice

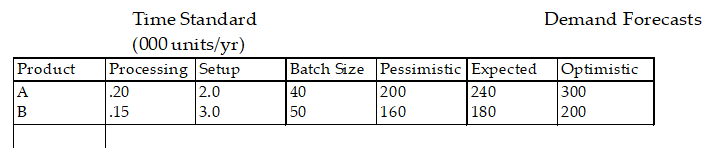

Table 5.2

High Tech, Inc. is producing two types of products: A and B. Both are produced at the same sawing operation. Because of demand uncertainties, the operations manager obtained three demand forecasts (pessimistic, expected, and optimistic) . The demand forecasts, batch sizes (units/batch) , processing times (hr/unit) , and setup times (hr/batch) follow.

The sawing machines operate on two 8-hour shifts, 5 days per week, and 50 weeks per year. The manager wants to maintain a 10 percent capacity cushion.

-Using the information from Table 5.2, how many hours of capacity can the company expect from each of its sawing machines?

A) less than 3500 hours

B) more than 3500 hours but less than 3700 hours

C) more than 3700 hours but less than 3900 hours

D) more than 3900 hours

Correct Answer:

Verified

Correct Answer:

Verified

Q65: Aggregate stock is any stock of items

Q66: _ is introduced by chance and results

Q67: Effective management of capacity includes only consideration

Q68: Setup time is the time required to

Q69: What is the capacity cushion and how

Q71: Little's Law is the mathematical relationship than

Q72: A bottleneck is an operation that has

Q73: Little's Law is a mathematical expression for

Q74: Typically, a larger capacity cushion is required

Q75: The difference of 100 % - Utilization