Multiple Choice

Table 5.2

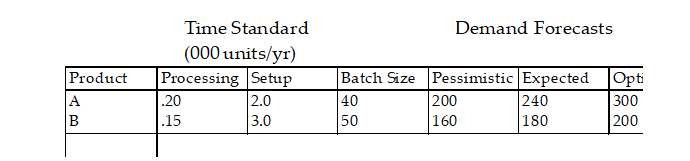

High Tech, Inc. is producing two types of products: A and B. Both are produced at the same sawing operation. Because of demand uncertainties, the operations manager obtained three demand forecasts (pessimistic, expected, and optimistic) . The demand forecasts, batch sizes (units/batch) , processing times (hr/unit) , and setup times (hr/batch) follow.

The sawing machines operate on two 8-hour shifts, 5 days per week, and 50 weeks per year. The manager wants to maintain a 10 percent capacity cushion.

-Using the information from Table 5.2, what is the maximum number of machines needed (assuming no reliance on short- term option) ?

A) less than or equal to 25

B) more than 25 but less than or equal to 28

C) more than 28 but less than or equal to 31

D) more than 31

Correct Answer:

Verified

Correct Answer:

Verified

Q5: _ is the degree to which equipment,

Q78: The _ is to do nothing and

Q79: Which one of the following statements about

Q80: A blocked operation is an operation that

Q81: Random variation is introduced by chance and

Q84: A decision tree is a schematic model

Q85: Process Management Triangle is made up of

Q86: The first step in the application of

Q87: In a manufacturing company, measuring capacity based

Q101: A capacity cushion is the amount of