Multiple Choice

Table

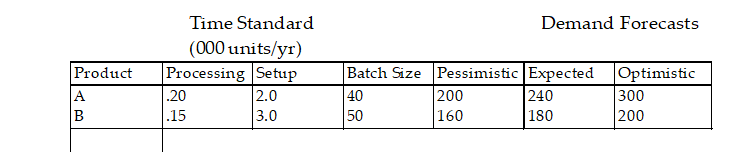

High Tech, Inc. is producing two types of products: A and B. Both are produced at the same sawing operation. Because of demand uncertainties, the operations manager obtained three demand forecasts (pessimistic, expected, and optimistic) . The demand forecasts, batch sizes (units/batch) , processing times (hr/unit) , and setup times (hr/batch) follow.

The sawing machines operate on two 8- hour shifts, 5 days per week, and 50 weeks per year. The manager wants to maintain a 10 percent capacity cushion.

-Using the information from Table 5.2, what is the minimum number of machines needed (assuming no reliance on short- term options) ?

A) less than or equal to 22

B) more than 22 but less than or equal to 25

C) more than 25 but less than or equal to 28

D) more than 28

Correct Answer:

Verified

Correct Answer:

Verified

Q55: Capacity is the maximum rate of output

Q125: Table <span class="ql-formula" data-value="5.3"><span class="katex"><span

Q126: The higher that process variability is, the

Q127: Wait time is not part of the

Q128: _ capacity is the maximum output that

Q131: In a tire manufacturing plant, measuring capacity

Q132: The theory of constraints is an approach

Q133: What is the meaning of diseconomies of

Q134: Fixing time is the additional time needed

Q135: Identify the three interrelated factors that implicitly