Multiple Choice

SCENARIO 19-4

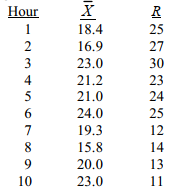

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits.The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours.The sample mean and range for each hour are listed below. She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds,respectively.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds,respectively.

-Referring to Scenario 19-4,suppose the supervisor constructs an R chart to see if the variability in collection times is in-control.What is the center line of this R chart?

A) 20.00

B) 20.56

C) 20.40

D) 24.00

Correct Answer:

Verified

Correct Answer:

Verified

Q103: SCENARIO 19-8<br>Recently,a university switched to a new

Q104: The SS method establishes ways to organize

Q105: Quick Changeover Techniques is among the tools

Q106: SCENARIO 19-3<br>A quality control analyst for a

Q107: SCENARIO 19-2<br>A political pollster randomly selects a

Q109: SCENARIO 19-5<br>A manufacturer of computer disks took

Q110: SCENARIO 19-4<br>A factory supervisor is concerned that

Q111: SCENARIO 19-6<br>The maker of a packaged candy

Q112: The SS method establishes ways to clean

Q113: SCENARIO 19-10<br>Below is the number of defective