Multiple Choice

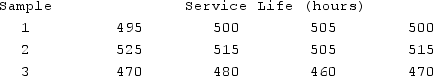

A design engineer wants to construct a sample mean chart for controlling the service life of a halogen headlamp his company produces. He knows from numerous previous samples that this service life is normally distributed with a mean of 500 hours and a standard deviation of 20 hours. On three recent production batches, he tested service life on random samples of four headlamps, with these results

What is the standard deviation of the sampling distribution of sample means for whenever service life is in control?

A) 5 hours

B) 6.67 hours

C) 10 hours

D) 11.55 hours

E) 20 hours

Correct Answer:

Verified

Correct Answer:

Verified

Q10: The purpose of statistical process control is

Q11: Consider the following information<br><img src="https://d2lvgg3v3hfg70.cloudfront.net/TB8594/.jpg" alt="Consider the

Q12: Approving the effort that occurs during the

Q13: A quality analyst wants to construct a

Q14: The traditional view is that the optimum

Q16: If a point on a control chart

Q17: Acceptance sampling, when it is used, is

Q18: Attributes need to be measured, whereas variable

Q19: A time-ordered plot of sample statistics is

Q20: Inspection is a(n)_ activity.<br>A)prevention.<br>B)capability analysis.<br>C)flawless<br>D)corrective.<br>E)appraisal.