Multiple Choice

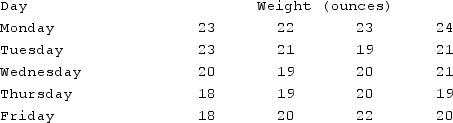

A quality analyst wants to construct a sample mean chart for controlling a packaging process. He knows from past experience that whenever this process is in control, package weight is normally distributed with a mean of 20 ounces and a standard deviation of two ounces. Each day last week, he randomly selected four packages and weighed each

If he uses upper and lower control limits of 22 and 18 ounces, what is his risk (alpha) of concluding this process is out of control when it is actually in control (Type I error) ?

A) 0.0026

B) 0.0456

C) 0.3174

D) 0.6826

E) 0.9544

Correct Answer:

Verified

Correct Answer:

Verified

Q41: If a process is performing as it

Q42: Processes that are in control eliminate variations.

Q43: This step in the control process includes

Q44: Run tests are useful in helping to

Q45: The traditional view is that the optimum

Q47: An x-bar control chart can only be

Q48: The traditional view is that the optimum

Q49: The chair of the operations management department

Q50: Studies on a bottle-filling machine indicate that

Q51: Concluding that a process is out of