Multiple Choice

Baldwin Printers has contracts to complete weekly supplements required by forty-two customers. For the year 2011, manufacturing overhead cost estimates total $1,840,000 for an annual production capacity of 20 million pages.

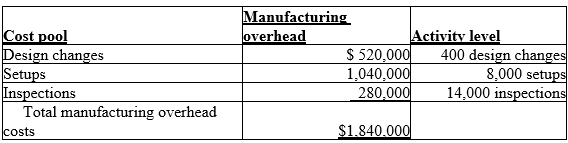

For 2011 Baldwin Printers has decided to evaluate the use of additional cost pools. After analyzing manufacturing overhead costs, it was determined that number of design changes, setups, and inspections are the primary manufacturing overhead cost drivers. The following information was gathered during the analysis:

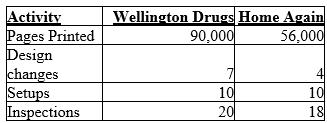

During 2011, two customers, Wellington Drugs and Home Again, are expected to use the following printing services:

-Assuming activity-cost pools are used,what are the activity-cost driver rates for design changes,setups,and inspections cost pools?

A) $1,300 per design change, $130.00per setup, $20 per inspection

B) $360 per design change, $3.20per setup, $6.40 per inspection

C) $1,680 per design change, $5.38 per setup, $42 per inspection

D) $286 per design change,$15.38 per setup,$20 per inspection

Correct Answer:

Verified

Correct Answer:

Verified

Q73: Baldwin Printers has contracts to complete weekly

Q74: Greater manufacturing overhead costs are associated with:<br>A)specialized

Q75: Reducing the number of production runs provides

Q76: Smaller cost distortions occur when the traditional

Q77: Tony's Skate Corporation manufactures two models of

Q79: The major reason for using practical capacity

Q80: Explain how traditional cost systems,using only unit

Q81: The selection of activity cost drivers requires

Q82: Transaction drivers,duration drivers,and intensity drivers.<br>a.For machine maintenance,identify

Q83: The best cost estimate for resources required