Multiple Choice

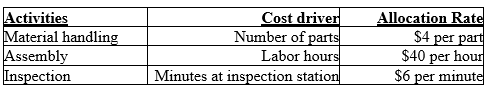

Merrill, Inc. manufactures remote controls. Currently the company uses a plant-wide rate for allocating manufacturing overhead costs. The plant manager believes it is time to refine the method of cost allocation and has the accounting department identify the primary production activities and their cost drivers:

The current traditional cost method allocates overhead costs based on direct labor hours using a rate of $ 400 per labor hour.

-What are the manufacturing overhead costs per remote control assuming an activity-based costing method is used and a batch of 50 remote controls are produced? The batch requires 100 parts,6 direct manufacturing labor hours,and 2.5 minutes of inspection time.

A) $8.00 per remote control

B) $13.10 per remote control

C) $48.00 per remote control

D) $655.00 per remote control

Correct Answer:

Verified

Correct Answer:

Verified

Q55: For service organizations,activity-based cost systems clarify appropriate

Q56: Unused capacity should be treated as a

Q57: Traditional cost systems are likely to overcost

Q58: It is important that the product costs

Q59: Advantages of a time-driven ABC system include:<br>A)data

Q61: According to an ABC system,M5 uses a

Q62: Logical cost allocation bases for overhead costs

Q63: ABC systems:<br>A)reveal activities that can be eliminated.<br>B)help

Q64: The use of unit-related measures to assign

Q65: Design of an activity-based cost system requires