Multiple Choice

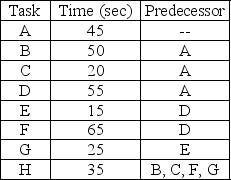

The process design team at a manufacturer has broken an assembly process into eight basic steps,each with a required time,and predecessor as shown in the table.There are 7.5 productive hours available in a day and the manufacturer wishes to produce 400 units.Balance the line by assigning tasks to workstations to fill up as much takt time as possible.Break ties by assigning the longest task first.What task(s) should be assigned at the third workstation?

A) B and E

B) D

C) C,E,and G

D) F

Correct Answer:

Verified

Correct Answer:

Verified

Q1: A legal service in a corporate acquisition

Q3: _ products involve no customization but _

Q11: A batch process is less flexible than

Q12: Operations managers and process engineers design a

Q13: The table depicts an assembly line that

Q18: The maximum allowable cycle time for a

Q19: The manager assigns tasks to workstations and

Q42: The manufacturing process used to make a

Q47: The Devon Tower graces the Oklahoma City

Q99: The point where the customer interfaces directly