Essay

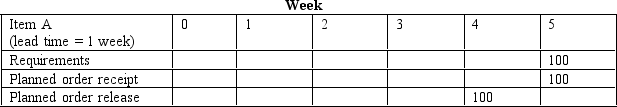

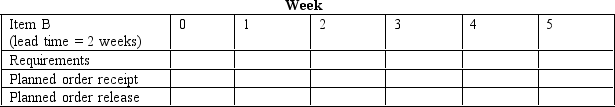

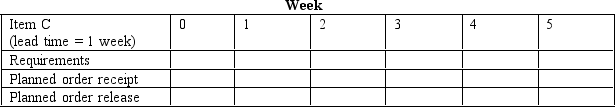

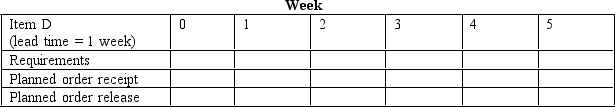

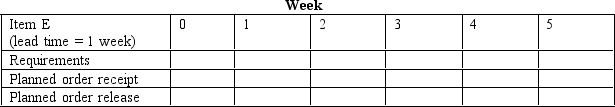

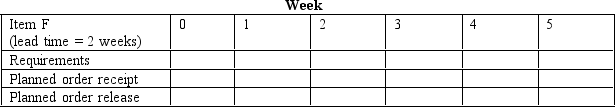

One unit of product A is made of two units of B and four units of C.B is made of two units of D and three units of E.C is made of three units of D and two units of F.A,C,D,and E have lead times of one week,and B and F have lead times of two weeks.If 100 units of A are required in week 5,develop the material requirements plan specifying when items are to be ordered and received.There are no units of inventory on hand.Hint: Since there are no units of inventory on hand,gross requirements will be equal to net requirements. 100 units of A should be ordered in the fourth week because these units are needed in the fifth week and the lead time is one week.

Correct Answer:

Verified

100 units of A would require 200 units...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

100 units of A would require 200 units...

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q58: Reorder point models require that stable demand

Q59: Based on systems thinking,changes to any part

Q60: The essence of MRP II is<br>A)feedback planning

Q61: _ are the starting point for actual

Q62: Order promising is best defined as:<br>A)time between

Q64: Gross requirements less the projected stock-on-hand,at time

Q65: Order promising by sales and marketing and

Q66: One unit of product A is made

Q67: The cumulative lead time for a secondary

Q68: Lot-for-lot sizing costs can be obtained by