Essay

John Morton, director of materials management for Computer Products Corporation (CPC) in San Jose, is now reviewing next year's plans for the supply of a component that is now purchased from Osiega Ltd., a company in Japan. The component is the PS100 power supply assembly that is used in many of CPC's products.

CPC pays the supplier more than $7 million per year for these units, and John wonders if money could be saved by developing another supplier for this component or if CPC should gear up to manufacture the power supply assemblies in-house within one of the CPC's own production plants.

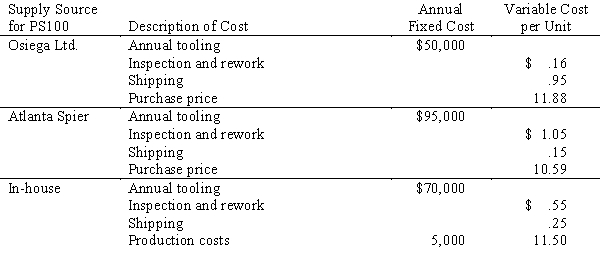

John's purchasing-analysis staff has developed the following estimates:  The purchasing-analysis group has learned that CPC will need about 550,000 of the PS100 units next year.

The purchasing-analysis group has learned that CPC will need about 550,000 of the PS100 units next year.

a.Which supply source provides the least cost for next year?

b.How many PS100 units would have to be bought next year for each of the sources to be the least-cost source?

Correct Answer:

Verified

a.TC = FC + vQ

TCOL = 50,000 + 12.99(550,00...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

TCOL = 50,000 + 12.99(550,00...

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q4: From the pre- and post-service view, transportation

Q14: The first, second, and third waves of

Q18: Pre-production services might include on-line training services,

Q21: Which of the following is false? To

Q25: Value can be increased by adding services

Q51: The organization that outsources still retains ownership

Q55: Historically, service work was outsourced before many

Q59: Define multinational enterprises. What challenges do they

Q61: Explain the notion of value chain integration.

Q68: The focus of preproduction services is on