Multiple Choice

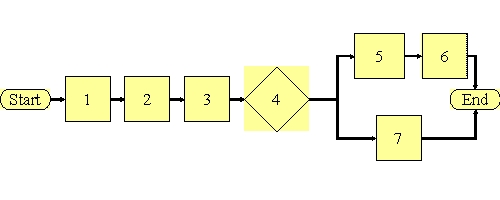

A medical equipment testing and calibration service is depicted in Figure 1. The customer usually brings the equipment to the service center. The service process requires service technicians to perform three process steps #1 to #3. Each technician is cross-trained so they can perform any of the three steps. The inspector does Step # 4 alone. After step #4, two parallel work activities are performed. That is, a shipping clerk packs the work (step 7) while a billing clerk prepares the invoice (step 5) simultaneously, and the customer is contacted by phone for pick-up (step 6) . The average throughput is 3 equipment units per hour.  Figure 1 Flow chart of the medical equipment testing and calibration service process

Figure 1 Flow chart of the medical equipment testing and calibration service process

The table below shows the work content of the process steps, activity times in minutes per unit, shared and non-shared work activities, and the type of resource required. There are 3 service technicians on duty: 1 inspector, 1 billing clerk, and 1 shipping clerk.

-An order fulfillment process normally operates two shifts a day, six days per week. Under normal conditions, 380 orders can be processed per shift. The weekly capacity is _____.

A) less than 1,000 orders per week

B) more than 1,000 orders but less than or equal to 2,000 order per week

C) more than 2,000 orders but less than or equal to 3,000 orders per week

D) more than 3,000 orders per week.

Correct Answer:

Verified

Correct Answer:

Verified

Q1: The Theory of Constraints is focused on

Q2: C&M Machining is developing plans for a

Q3: A pharmacy lab is used for

Q4: Define a revenue management system (RMS) and

Q5: Capacity lag strategy results in constant capacity

Q7: According to the Theory of Constraints, _

Q8: Perform a capacity analysis of the process

Q9: Average safety capacity (%) is computed as:<br>A)

Q10: Perform a capacity analysis of the process

Q11: Changing labor skill mix is a means