Essay

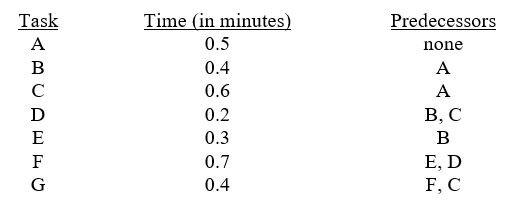

Consider the following assembly line information for manufacturing the latest cell phone.  The firm wants to produce 80 cell phones per hour.

The firm wants to produce 80 cell phones per hour.

a.What is the required cycle time?

b.Balance the assembly line using your choice of balancing heuristic, with the goal of minimizing the number of workstations needed? (Specify the task(s) assigned to each workstation.)

c.What is the efficiency of your assembly line?

d.Is this a good assembly line balancing solution? Explain.What do you recommend?

Correct Answer:

Verified

a.CT = A/R = 60/80 = 0.75 minutes per ce...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q31: Explain assembly-line balancing. Discuss the three types

Q49: Changes in goods and services for a

Q50: Differentiate among product layout, process layout, cellular

Q51: All of the following are true regarding

Q52: An assembly line with 28 activities is

Q53: Job enlargement approaches give workers more variety

Q53: All of the following are limitations to

Q58: Which of the following is not a

Q77: The objective of assembly-line balancing is to

Q92: Self-managed teams perform entire jobs, rather than