Essay

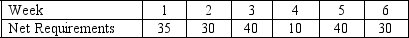

A company that makes construction equipment is exploring different lot sizing approaches to its MRP schedule: lot-for-lot (LFL), fixed order quantity (FOQ) using the EOQ, and period order quantity (POQ).It costs $100 to set up the production line to produce hydraulic jacks and the carrying cost per unit per week is $1.Annual demand is expected to be 1550 jacks.For planning purposes, the company uses a 50-week work year and disregards the effects of initial inventory and safety stock.The net requirements for hydraulic jacks for the next six weeks are:

a.Using a LFL approach, what is the lot size in week 3?

a.Using a LFL approach, what is the lot size in week 3?

b.What is the total cost for the LFL method?

c.What is the Fixed order quantity (FOQ) using the EOQ approach?

d.What is the beginning inventory for week 5 using the FOQ approach?

e.What is the total cost using the FOQ method?

f.What is the period order quantity?

g.What is the ending inventory for week 4 using the POQ method?

h.What is the total cost using the POQ approach?

Correct Answer:

Verified

a.Lot-for-lot (LFL):

b.Set-up costs 6 ...

b.Set-up costs 6 ...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q9: Which lot sizing rule might use the

Q11: Resources include materials, equipment, facilities, information, technical

Q13: A metal shop currently has a work

Q16: Explain the three lot-sizing methods, and under

Q17: The direct inputs to material requirements planning

Q27: Lot sizing rules on a parent item

Q65: Short-term changes in facilities and equipment are

Q79: A company currently has no items in

Q87: Aggregate planning and disaggregation methods in goods-producing

Q102: Describe the options that managers have for