Essay

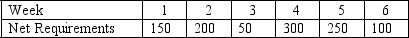

A company assembles microcomputers for sale to computer stores.They are trying to decide which lot sizing approach to use for developing their MRP schedules: lot-for-lot (LFL), fixed order quantity (FOQ) using the EOQ approach, or period order quantity (POQ).The set-up cost is $1000 per order, the inventory carrying cost is $2.50 per week per unit and the annual demand for the computers is 10,000 units.The company is using a 50-week work year and disregarding the effects of initial inventory and safety stock.The estimated net requirements for the microcomputers for the next six weeks are:

a.Using the LFL method, what is the size of the production lot for week 2?

a.Using the LFL method, what is the size of the production lot for week 2?

b.What is the total cost using the LFL method?

c.What is the economic order quantity (EOQ)?

d.What is the ending inventory in week 3 using the EOQ approach?

e.What is the total cost using the EOQ method?

f.What is the period order quantity (POQ)?

g.What is the beginning inventory in week 4 using the POQ approach?

h.What is the total cost using the POQ method?

Correct Answer:

Verified

a.Lot-for-lot (LFL):

b.Set-up costs =...

b.Set-up costs =...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q8: What is capacity requirements planning (CRP)?

Q26: Resource management deals primarily with managing inventories

Q58: A level production strategy maintains constant inventory

Q66: The lower the skill requirements of the

Q77: Good solutions to aggregate planning situations can

Q79: Define Material Requirements Planning (MRP) and how

Q80: A scheduled receipt for an outside vendor

Q85: The MPS is developed in the same

Q86: The words "product family," "budget allocation" and

Q106: Define resource management and list its key