Essay

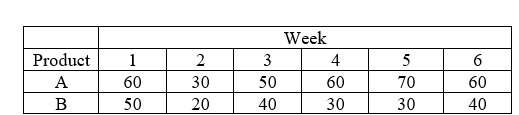

A firm produces two models of pagers, products A and B, on a produce to stock basis and is trying to develop a master production schedule for its operation. Safety stock is 30 for product A and 20 for product B. Fixed lot sizes are 70 for product A and 40 for product B. The beginning inventories are 30 for A and 30 for B. The demand for these products comes from many different sources, but the total weekly demand for each of the next six weeks is given as follows:

a. What is the production quantity for Product A for week 3?

b. What is the ending inventory for Product A for week 3?

c. What is the production quantity for Product B for week 5?

d. What is the beginning inventory for Product B for week 5?

Correct Answer:

Verified

a.0

Master Production Schedule...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

Master Production Schedule...

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q9: Explain the three levels of resource planning.

Q40: A paint company has the following aggregate

Q41: A local company makes athletic clothing and

Q42: Which lot sizing rule is best when

Q43: Lot sizing is the process of using

Q43: The purpose of the master schedule is

Q44: Which of the following is not an

Q46: Setting order sizes and schedules for individual

Q48: The bill of material for end item

Q50: A firm produces one product on a