Essay

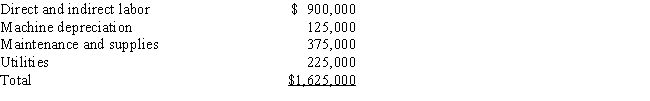

The Kwanika Co.operates in a lean manufacturing environment.During its first year of operations,Kwanika budgeted for 40,000 hours in the production of 100,000 units in its cell X-22.Material costs were $7 per unit.Cell X-22 conversion costs were budgeted for the year as follows:

During January,material for 8,400 units was purchased on account.There were 8,200 units manufactured and 8,000 were sold shipped to customers for $35 each.Journalize: (a)the material purchases; (b)the application of conversion costs; (c)the transfer from work in process to finished goods; and (d)the sales (were made on account)and associated cost of goods sold for the month of January.

During January,material for 8,400 units was purchased on account.There were 8,200 units manufactured and 8,000 were sold shipped to customers for $35 each.Journalize: (a)the material purchases; (b)the application of conversion costs; (c)the transfer from work in process to finished goods; and (d)the sales (were made on account)and associated cost of goods sold for the month of January.

Correct Answer:

Verified

Correct Answer:

Verified

Q19: From the foregoing information,determine the budgeted cell

Q20: Long setups and large batch sizes result

Q22: Lean manufacturing is also called make-to-order manufacturing.

Q23: Connally Company's payroll department required that every

Q25: Push manufacturing (made-to-stock)is a traditional approach to

Q26: Alaskan Pattern Company makes dressmakers' patterns using

Q27: From the above schedule of activity costs,determine

Q29: In a lean environment, the journal entry

Q31: Lead time includes both value-added time and

Q94: From the foregoing information, determine the amount