Multiple Choice

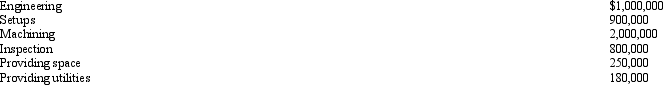

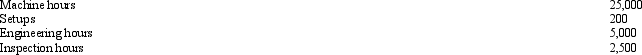

Figure 4-19 Owens Corporation produces specially machined parts.The parts are produced in batches in one continuous manufacturing process.Each part is custom produced and requires special engineering design activity (based on customer specifications) .Once the design is completed, the equipment can be set up for batch production.Once the batch is completed, a sample is taken and inspected to see if the parts are within the tolerances allowed.Thus, the manufacturing process has four activities: engineering, setups, machining, and inspecting.In addition, there is a sustaining process with two activities: providing utilities (plantwide) and providing space.Costs have been assigned to each activity using direct tracing and resource drivers: Activity drivers for each activity have been identified and their practical capacities listed:

Activity drivers for each activity have been identified and their practical capacities listed: The costs of facility-level activities are assigned using machine hours.

The costs of facility-level activities are assigned using machine hours.

-

Refer to Figure 4-19.What is (are) the batch-level activity(ies) ?

A) engineering

B) setups

C) inspecting

D) all of these

Correct Answer:

Verified

Correct Answer:

Verified

Q20: The use of unit-based activity drivers to

Q30: An activity-based costing system uses which of

Q128: Unit-based product costing uses which of the

Q131: Unit-level product costing assigns<br>A) direct materials and

Q134: A costing system that uses actual costs

Q135: For a labor-intensive manufacturing operation, which of

Q135: A(n)_ is a grouping of logically related

Q136: Figure 4-6 Cabrini Company produces two products:

Q137: King Manufacturing has four categories of overhead.The

Q144: Which of the following quantities is an