Essay

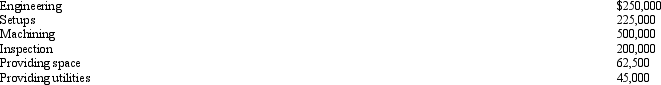

Godwin Corporation produces specially machined parts.The parts are produced in batches in one continuous manufacturing process.Each part is custom produced and requires special engineering design activity (based on customer specifications).Once the design is completed, the equipment can be set up for batch production.Once the batch is completed, a sample is taken and inspected to see if the parts are within the tolerances allowed.Thus, the manufacturing process has four activities: engineering, setups, machining, and inspecting.In addition, there is a sustaining process with two activities: providing utilities (plantwide) and providing space.Costs have been assigned to each activity using direct tracing and resource drivers:

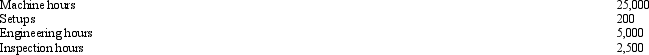

Activity drivers for each activity have been identified and their practical capacities listed:

Activity drivers for each activity have been identified and their practical capacities listed:

The costs of batch-level activities are assigned using number of setups.

The costs of batch-level activities are assigned using number of setups.

The costs of facility-level activities are assigned using machine hours.

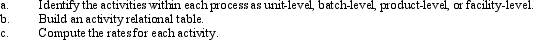

Required:

Correct Answer:

Verified

_TB2043_00...

_TB2043_00...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q29: Which of the following is NOT an

Q53: The proportion of an overhead activity consumed

Q85: Kramer Company has decided to use a

Q86: Figure 4-21 Jones Manufacturing uses an activity-based

Q87: Figure 4-1 Adams Company predicted factory overhead

Q89: Figure 4-16 Newman Company recently installed an

Q92: Figure 4-21 Jones Manufacturing uses an activity-based

Q93: Figure 4-9 Winter Manufacturing has four categories

Q94: Figure 4-21 Jones Manufacturing uses an activity-based

Q152: If operations run on less than full