Multiple Choice

Use this information for questions that refer to the United Tools case.

Terry Harter is marketing manager for United Tools and Mike O'Reilly is the firm's logistics manager. They work together to make decisions about how to get United's hand and power tools to its customers - a mix of manufacturing plants and final consumers (who buy United tools at a hardware store) . United Tools does not own its own transport facilities and it works with wholesalers to reach its business customers.

Together, Harter and O'Reilly try to coordinate transporting, storing, and product handling activities to minimize cost while still achieving the customer service level their customers and intermediaries want. This usually requires that United keep an inventory of most of its products on hand, but demand for its products is fairly consistent over time so inventory is easy to manage.

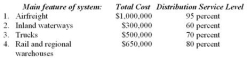

Harter has identified four options for physical distribution systems she could use to reach two of her key wholesalers, Ralston Supply and Ricotta Tool Co. The total cost for each option--and the distribution service levels that can be achieved--are as follows:  Ralston Supply expects a very high level (90 percent) of distribution customer service. Ricotta Tool Co. is willing to settle for a 70 percent customer service level, even if that means some products will occasionally be out of stock, if it gets products at a lower price.

Ralston Supply expects a very high level (90 percent) of distribution customer service. Ricotta Tool Co. is willing to settle for a 70 percent customer service level, even if that means some products will occasionally be out of stock, if it gets products at a lower price.

For its large retail hardware customers (like Home Depot) , United regularly ships smaller orders directly to individual stores or in some cases to the retail chain's warehouses. Cross-country shipments usually go by rail while regional shipments usually go by truck.

-United's shipments to international markets often rely on containerization. The likely reason for this is that

A) the tools are shipped by airfreight.

B) it makes it easier to move shipments between different transportation modes.

C) containerization is very useful for small, frequent shipments.

D) containerization allows a firm to carry less inventory.

E) all of the above are benefits of containerization.

Correct Answer:

Verified

Correct Answer:

Verified

Q2: Just-in-time delivery reduces storing and handling costs

Q35: At least _ percent of all freight

Q78: Public warehouses (compared to private warehouses) provide

Q100: Regarding alternative transporting modes:<br>A) trucks are good

Q150: Compared to private warehouses, PUBLIC warehouses:<br>A) are

Q151: A manufacturer having irregular need for regional

Q152: Regarding alternative transporting modes, which of the

Q155: When planning physical distribution, the marketing manager

Q191: Storing of goods is necessary when<br>A) there

Q213: The primary function of a _ is