Essay

Janie Hochevar, director of production at the center, has decided to record the number of defective labels in random daily samples on control charts. Janie estimates that 1.5 percent loose labels is typical when the labeling process is in control.

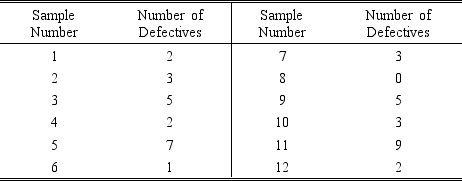

Twelve daily samples, each consisting of 200 pairs of jeans, were selected and examined. The number of defective labels found in each sample is shown below.

a. Determine the center line and the 3s control limits for the p chart.

b. Decide if the labeling operation is in control.

Correct Answer:

Verified

a. Center line = .015

Upper control limi...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

Upper control limi...

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q4: A graph showing the probability of accepting

Q12: The Malcolm Baldrige National Quality Award was

Q16: Rejecting a poor-quality lot would be a<br>A)Type

Q19: The process mean and standard deviation can

Q21: Consumer's risk is<br>A)the same concept as the

Q25: Six Sigma represents a quality level of

Q32: DFSS stands for<br>A) Defects Found Sifting and

Q41: The quality control department of a company

Q56: The general practice in quality control is

Q65: The following data represent the filling weights