Multiple Choice

Parts manufactured by an injection molding process are subjected to a compressive strength test.We monitor the compressive strength of the parts manufactured by this process using an  and an s control chart.Samples of size 9 are taken at regular intervals,and their mean compressive strength (in psi = pounds per square inch) and standard deviation are plotted on the charts in time order.The overall mean of the sample means is

and an s control chart.Samples of size 9 are taken at regular intervals,and their mean compressive strength (in psi = pounds per square inch) and standard deviation are plotted on the charts in time order.The overall mean of the sample means is  = 81.2 psi,and the mean of the sample standard deviations is

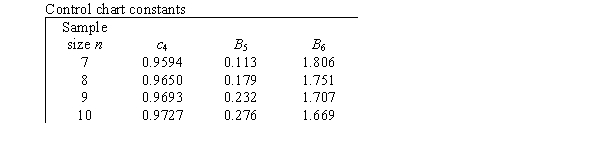

= 81.2 psi,and the mean of the sample standard deviations is  = 2.9 psi.The control chart constants are (partially) reproduced below.

= 2.9 psi.The control chart constants are (partially) reproduced below.  What is the center line for the s chart?

What is the center line for the s chart?

A) 2.8 psi

B) 2.9 psi

C) 3 psi

D) 5.0 psi

Correct Answer:

Verified

Correct Answer:

Verified

Q40: A bank is interested in improving the

Q41: What is the definition of rational subgroups?<br>A)They

Q42: An important characteristic in the proper operation

Q43: It is said that "the first step

Q44: Parts manufactured by an injection molding process

Q46: What is the name of a chart

Q47: A random sample of items was selected

Q48: Which of the following is an example

Q49: A variable is measured periodically on a

Q50: You have been invited to give a