Essay

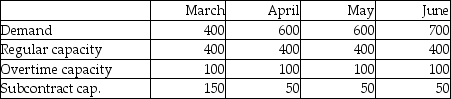

Byron's Manufacturing makes tables.Demand for the next four months and capacities of the plant are shown in the table below.Unit cost on regular time is $40.Overtime cost is 150% of regular time cost.Subcontracting is available in substantial quantity at $75 per unit.Holding costs are $5 per table per month; back orders cost the firm $10 per unit per month.Byron's management believes that the transportation algorithm can be used to optimize this scheduling problem.The firm has 50 units of beginning inventory and anticipates no ending inventory.

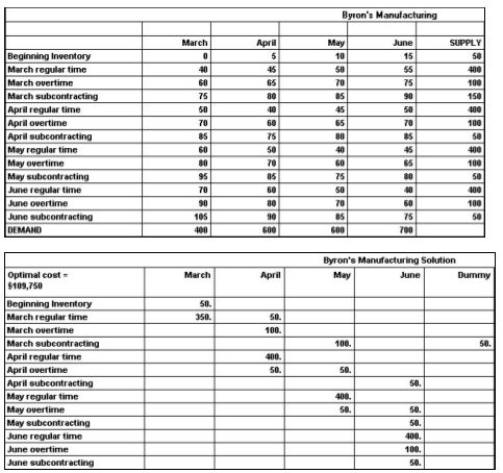

Answer the following questions based on the data table and solution table shown below.

Answer the following questions based on the data table and solution table shown below.  a.How many units will be produced on regular time in June?

a.How many units will be produced on regular time in June?

b.How many units will be produced by subcontracting over the four-month period?

c.What will be the inventory at the end of April?

d.What will be total production from all sources in April?

e.What will be the total cost of the optimum solution?

f.Does the firm utilize the expensive options of subcontracting and back ordering? When; why?

Correct Answer:

Verified

(a)400; (b)250; (c)0; (d)550; (e)Total C...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q50: Eagle Fabrication has the following aggregate demand

Q51: Golden Eagle Machine Works has the following

Q53: In aggregate planning, the amount of overtime

Q59: If a service firm were to attempt

Q60: Aggregate planning would entail which of the

Q70: The objective of aggregate planning is usually

Q86: Mixed strategies in aggregate planning may utilize

Q90: What is the primary management challenge when

Q115: Finding an ideal mixed strategy is complicated

Q116: Which of the following aggregate planning strategies