Essay

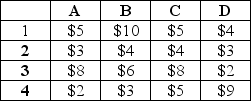

A national firm has beef jerky processing facilities in Locations 1,2,3,and 4.They ship to central distributors (represented as A,B,C,and

D)handling four regions of the country.The per-unit shipping costs between each possible combination of locations are shown in the following table.

The processing facility locations are capable of monthly production (in tons)as follows:

Location 1: 600

Location 2: 350

Location 3: 475

Location 4: 850

The central distributors have firm commitments for the following quantities:

Distributor A: 650

Distributor B: 725

Distributor C: 400

Distributor D: 500

What is the lowest-cost shipping arrangement that can be made between the plant locations and distributors and what is the annual shipping cost?

Correct Answer:

Verified

The optimal tableau is:  Total...

Total...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q6: Table 13.4<br>Royal Flush Plumbing Supplies has the

Q27: The load-distance model is used to minimize

Q65: Table 13.5<br>Paul's Pretzels manufactures and distributes gourmet

Q86: Table 13.6<br>Union Fork, Inc. has five distribution

Q93: Which location shift would qualify as forward

Q94: Excel Products is planning a new warehouse

Q95: Five sources exist for the civet cat

Q98: Table 13.6<br>Union Fork, Inc. has five distribution

Q99: The Burdell Company has four distribution centers

Q106: Because Geographical Information System (GIS) tools are