Essay

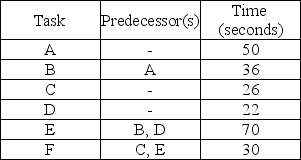

A company is designing a product layout for a new product.It plans to use this production line eight hours a day in order to meet a schedule of 400 units per day.The tasks necessary to produce this product are detailed in the table below.

a.Draw the network described in the table.

a.Draw the network described in the table.

b.Without regard to a production schedule,what is the minimum possible cycle time (in seconds)for this situation;what is the maximum?

c.What is the required cycle time (in seconds)in order to meet the schedule?

d.What is the theoretical minimum number of workstations needed to meet the schedule?

e.Balance this line using longest processing time.

f.What is the efficiency of the balance obtained in part e?

Correct Answer:

Verified

The network diagram appears below.Minimu...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q15: The assumption of stability of demand is

Q19: An assembly line consists of 158 tasks

Q42: _ is that element of balancing a

Q44: The _ is a non-numeric method for

Q73: Cycle time is computed as:<br>A) desired output

Q74: Briefly explain what "slotting" is. Why is

Q81: Identify the seven fundamental layout strategies. Describe

Q150: A company is trying to balance production

Q156: A focused work center is well suited

Q317: The biggest advantage of a product layout