Essay

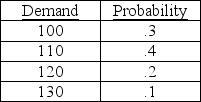

A product has a reorder point of 110 units,and is ordered four times a year.The following table shows the historical distribution of demand values observed during the reorder period.

Managers have noted that stockouts occur 30% of the time with this policy,and question whether a change in inventory policy,to include some safety stock,might be an improvement.The managers realize that any safety stock would increase the service level,but are worried about the increased costs of carrying the safety stock.Currently,stockouts are valued at $20 per unit per occurrence,while inventory carrying costs are $10 per unit per year.What is your advice? Do higher levels of safety stock add to total costs,or not? What level of safety stock is best?

Managers have noted that stockouts occur 30% of the time with this policy,and question whether a change in inventory policy,to include some safety stock,might be an improvement.The managers realize that any safety stock would increase the service level,but are worried about the increased costs of carrying the safety stock.Currently,stockouts are valued at $20 per unit per occurrence,while inventory carrying costs are $10 per unit per year.What is your advice? Do higher levels of safety stock add to total costs,or not? What level of safety stock is best?

Correct Answer:

Verified

The cheapest inventory policy...

The cheapest inventory policy...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q9: Which category of inventory holding costs is

Q16: In the production order quantity (POQ) model,

Q35: In the simple EOQ model, if annual

Q49: If daily demand is constant at 10

Q93: An organization has had a policy of

Q99: Assume two inventory problems with identical demand,

Q117: Compare the assumptions of the production order

Q125: When is a good time for cycle-counting

Q195: In the production order quantity model, the

Q215: What is a fixed-period system?