Short Answer

SCENARIO 19-4

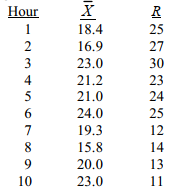

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds)is too erratic and adversely affects expected profits.The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours.The sample mean and range for each hour are listed below. She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds,respectively.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds,respectively.

-Referring to Scenario 19-4,what is the value of the Cpk index?

Correct Answer:

Verified

Correct Answer:

Verified

Q67: SCENARIO 19-10<br>Below is the number of defective

Q68: Which of the following is one of

Q69: Total Productive Maintenance focuses on preventing the

Q70: The focus of Lean Six Sigma is

Q71: The Shewhart-Deming cycle plays an important role

Q73: Common causes of variation represent variation due

Q74: SCENARIO 19-3<br>A quality control analyst for a

Q75: A capability index is used to measure

Q76: Which famous statistician developed the 14 Points

Q77: SCENARIO 19-3<br>A quality control analyst for a