Essay

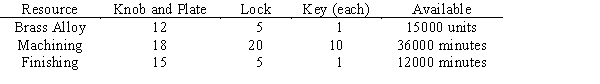

Larkin Industries manufactures several lines of decorative and functional metal items. The most recent order has been for 1200 door lock units for an apartment complex developer. The sales and production departments must work together to determine delivery schedules. Each lock unit consists of three components: the knob and face plate, the actual lock itself, and a set of two keys. Although the processes used in the manufacture of the three components vary, there are three areas where the production manager is concerned about the availability of resources. These three areas, their usage by the three components, and their availability are detailed in the table.

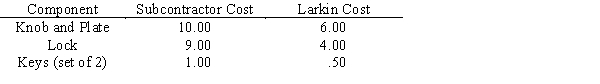

A quick look at the amounts available confirms that Larkin does not have the resources to fill this contract. A subcontractor, who can make an unlimited number of each of the three components, quotes the prices below.

Develop a linear programming model that would tell Larkin how to fill the order for 1200 lock sets at the minimum cost.

Correct Answer:

Verified

Let

PM = the number of knob and plate un...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

PM = the number of knob and plate un...

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q40: Department 3 has 2500 hours.Transfers are allowed

Q52: Double-subscript notation for decision variables should be

Q53: National Wing Company (NWC) is gearing up

Q55: The dual price for a constraint that

Q56: A company makes two products from steel;

Q57: Discuss the need for the use of

Q58: ?In a production scheduling LP, the demand

Q60: If a real-world problem is correctly formulated,

Q62: The production scheduling problem modeled in the

Q63: Evans Enterprises has bought a prime parcel