Multiple Choice

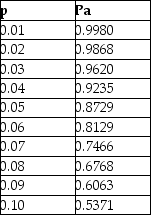

Champion Cooling Company has developed a sampling plan calling for a sample size of 25 and an acceptance number of 1. The proportion defective and probability of acceptance appear in the table. Floyd Electric, their supplier ships whatever Champion Cooling asks; sometimes the lot size is as small as 30 units and it has been as large as 10,000 units. Champion Cooling decides to stick with what they know, a sample size of 25 and an acceptance number of 1 despite advice to the contrary. Which statement regarding their sampling plan is best?

A) The average outgoing quality level will remain constant since the sample size and the acceptance number do not change.

B) The average outgoing quality level will vary as the lot size varies, but the average outgoing quality limit will remain constant.

C) The incoming fraction defective that produces the average outgoing quality limit will remain the same regardless of lot size.

D) The incoming fraction defective that produces the average outgoing quality limit will vary as the lot size varies.

Correct Answer:

Verified

Correct Answer:

Verified

Q1: Use Table G.1 for the following question.

Q2: A sequential sampling plan generally lowers the

Q3: Which one of the following alternatives will

Q4: This OC curve represents a sampling plan

Q6: A company is developing an acceptance sampling

Q7: A lot of 2,000 items has just

Q8: Discuss producer's risk and consumer's risk.

Q9: Which of the following is an example

Q10: For a given AQL and LTPD, which

Q11: Which of the following statements is True?<br>A)