Essay

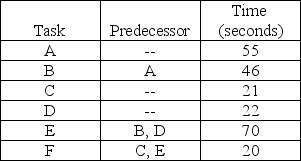

A company is designing a product layout for a new product. It plans to use this production line eight hours a day in order to meet a schedule of 300 units per day. The tasks necessary to produce this product are detailed in the table below.

(a) Draw the network described in the table.

(a) Draw the network described in the table.

(b) Without regard to a production schedule, what is the minimum possible cycle time (in seconds) for this situation; what is the maximum?

(c) What is the required cycle time (in seconds) in order to meet the schedule?

(d) What is the theoretical minimum number of workstations needed to meet the schedule?

(e) Balance this line using longest processing time.

(f) What is the efficiency of the balance obtained in part e?

Correct Answer:

Verified

Correct Answer:

Verified

Q2: One of the major advantages of process-oriented

Q3: Utilization of the total "cube" is the

Q4: Which of the following is used by

Q5: _ is a method of giving an

Q6: Job lots are groups or batches of

Q7: Who first developed the work sampling method?<br>A)

Q8: Activity charts help analyze:<br>A) movement of people

Q9: In assembly-line balancing, cycle time (the ratio

Q10: If the schedule calls for the production

Q11: Suppose that a time study analyst takes