Essay

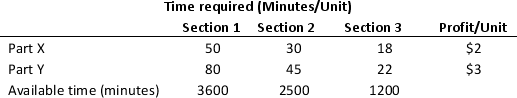

The supervisor of a production company is trying to determine the number of two assembling parts, Part X and Part Y to be produced per day in three different sections of the plant. The time required for the production along with the profit contribution for each part are given in the following table:

Each part made (X and Y) must be processed in each of the three sections. No more than 60 units of Part X can be produced, but up to 70 units of Part Y can be produced per day. The company already has orders for 30 units of Part Y that must be satisfied. a. Develop a linear programming model and solve the model to determine the optimal production quantities of parts X and Y. b. If more time could be made available in Section 2, how much worth would it be?

Correct Answer:

Verified

a. Let P1 = number of units of Part X pr...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q9: Geometrically, binding constraints intersect to form the<br>A)subspace.<br>B)optimal

Q11: The _ Report generated by Excel Solver

Q12: The intersections of half spaces represent_.<br>A) objective

Q14: A mathematical function in which each variable

Q15: The points where constraints intersect on the

Q17: A _ refers to a constraint that

Q18: When formulating a constraint, care must be

Q20: Reference - 8.1: Use the information given

Q21: Northwest California Ventures Ltd. has decided to

Q30: _ is the situation in which no