Essay

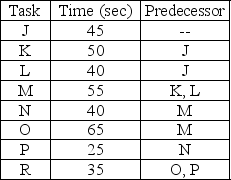

The process design team at a manufacturer has broken an assembly process into eight basic steps,each with a required time,and predecessor as shown in the table.There are 8 productive hours available in a day and the manufacturer wishes to produce 400 units using seven workers-one for each station.

Balance the line according to the longest operation rule and calculate the percent idle time.Using the same arrangement of tasks at work stations,what is the greatest output that can be achieved in an eight-hour day and what is the percent idle time of this design?

Balance the line according to the longest operation rule and calculate the percent idle time.Using the same arrangement of tasks at work stations,what is the greatest output that can be achieved in an eight-hour day and what is the percent idle time of this design?

Correct Answer:

Verified

The takt time is 8 ∗ 60 ∗ 60/400 = 72 se...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q3: _ products involve no customization but _

Q4: Cycle time is the sum of all

Q8: Make-to-stock products are typically produced using a

Q28: In a service process,the greater the emphasis

Q31: These three tables show the floor layout

Q34: The table depicts an production line that

Q37: The product process matrix uses a scale

Q43: A sporting apparel manufacturer that produces t-shirts

Q50: A customer service function at an insurance

Q92: Why are process decisions important?