Multiple Choice

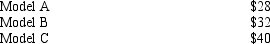

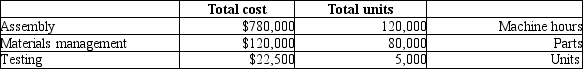

Orlando Avionics makes three types of radios for small aircraft-model A, model B, and model C. The manufacturing operations are mechanized and there is no direct labor. Manufacturing overhead costs are significant, and Orlando has adopted an activity-based costing system. Direct materials costs per unit for each model are as follows:  Orlando has three activities-assembly, materials management, and testing. The cost driver for assembly is machine hours. The cost driver for materials management is number of parts, and the cost driver for testing is the number of units of product. Total costs and production volumes for the year 2012 were estimated as follows:

Orlando has three activities-assembly, materials management, and testing. The cost driver for assembly is machine hours. The cost driver for materials management is number of parts, and the cost driver for testing is the number of units of product. Total costs and production volumes for the year 2012 were estimated as follows: The Model C radio requires 19 parts to construct, and also requires 20.5 machine hours of processing. What is the manufacturing cost to make one unit of Model C?

The Model C radio requires 19 parts to construct, and also requires 20.5 machine hours of processing. What is the manufacturing cost to make one unit of Model C?

A) $206.25

B) $176.00

C) $126.50

D) $166.25

Correct Answer:

Verified

Correct Answer:

Verified

Q34: Appalachee Company produces gaskets for the automotive

Q36: Which of the following would most likely

Q47: An activity-based costing system would be of

Q69: Johnson Production Company uses just-in-time production and

Q70: Nemesis Company manufactures water skis. Nemesis pursues

Q75: Morley Manufacturing is considering the manufacture of

Q76: Martin Manufacturers produces 3 models of industrial

Q77: Kenney Company uses activity-based costing to account

Q124: Costs incurred after the company sells poor-quality

Q141: In a just-in-time costing system, the entry