Multiple Choice

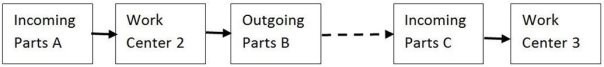

Consider the adjacent work stations in this two card kanban system. Work Center 3 has just pulled the Incoming Parts C box to their work station. What happens to the cards in the Incoming Parts C box and at the work station?

A) The move card at their station goes in the Incoming Parts C box and the production card is pulled from the Incoming Parts C box to signal the worker at Work Center 2 that there is a need to produce material.

B) The production card at the station is passed back to Work Center 2 as a signal to produce more material and the move card is left at Work Center 3 to signal that they are ready to accept materials when they are complete at Work Center 2.

C) The move card at their station goes in the box they will send downstream to Work Center 4 and the production card is placed at the Work Center 3 station while they are working on this batch of material.

D) The production card at their station goes in the Incoming Parts C box and the move card is pulled from the Incoming Parts C box to signal the worker at Work Center 2 that there is a need to move material.

Correct Answer:

Verified

Correct Answer:

Verified

Q2: In a lean system when a process

Q3: Lean thinking in the production environment has

Q4: The term just-in-time production is used synonymously

Q5: Lean supply chain management also seeks to

Q6: Lean's focus on inventory reduction prioritizes raw

Q7: The delivery lead time was highly variable

Q8: The receiving department accepts a shipment, confirms

Q9: The analogy of rocks in a river

Q10: Since a Lean manufacturer has very little

Q11: Consider the adjacent work stations in this