Essay

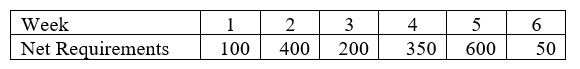

A manufacturing company is trying to determine the best lot-sizing approach to take when developing an MRP schedule: lot-for-lot (LFL), fixed order quantity (FOQ) using the EOQ, or period order quantity (POQ).The ordering cost is $504 per order, the inventory carrying cost is $1 per week per unit, and the annual demand for the product is 15,000 units.They are using a work schedule for a 50-week work year.They are disregarding the effects of initial inventory and safety stock at the present time.The estimated net requirements for their product for the next six weeks are:

a.Using LFL, what is the size of the production lot in week 3?

a.Using LFL, what is the size of the production lot in week 3?

b.Using LFL, what is the total cost for this method?

c.What is the EOQ needed?

d.What is the beginning inventory in week 4 using FOQ method?

e.What is the total cost for using the FOQ approach?

f.What is the POQ size for production lots?

g.What is the ending inventory for week 5 using POQ method?

h.What is the total cost for using the POQ approach?

Correct Answer:

Verified

a.Lot-for-lot (LFL):

b.Set-up costs (6...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

b.Set-up costs (6...

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q16: Explain the three lot-sizing methods, and under

Q17: The direct inputs to material requirements planning

Q20: A company is interested in developing a

Q22: The Academic Company mixes and bottles a

Q24: Increasing the output rate without changing existing

Q24: An electronics company wants to develop an

Q25: If a work center load report indicates

Q26: Define a Master Production Schedule (MPS) and

Q27: Lot sizing rules on a parent item

Q79: A company currently has no items in