Essay

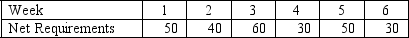

It is time for a company to do its MRP schedule, but they aren't sure which lot sizing approach to use: lot-for-lot (LFL), fixed order quantity (FOQ) using the EOQ approach, or period order quantity (POQ).They have the following information regarding the product they wish to produce:

Carrying costs = $1 per unit per week

Carrying costs = $1 per unit per week

Set-up costs = $125

Annual demand = 2000 units

Work year = 50 weeks

a.What is the production lot size for week 2 using the LFL method?

b.What is the total cost using the LFL approach?

c.What is the fixed order quantity (EOQ) using the EOQ approach?

d.What is the beginning inventory in week 3 using the FOQ approach?

e.What is the total cost using the FOQ method?

f.What is the period order quantity (POQ)?

g.What is the ending inventory in week 4 using the POQ approach?

h.What is the total cost using the POQ method?

Correct Answer:

Verified

a.Lot-for-lot (LFL):

b.Set-up costs = ...

b.Set-up costs = ...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q22: The Academic Company mixes and bottles a

Q24: An electronics company wants to develop an

Q24: Increasing the output rate without changing existing

Q25: If a work center load report indicates

Q26: Define a Master Production Schedule (MPS) and

Q28: Capacity requirements are computed by multiplying the

Q29: A(n) _ is a statement of how

Q30: The purpose of aggregate planning is to<br>A)Minimize

Q31: The Pacific Chemical Company produces high quality

Q32: Which lot sizing rule might base the