Multiple Choice

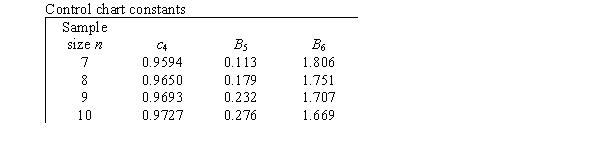

Parts manufactured by an injection molding process are subjected to a compressive strength test.We wish to monitor the compressive strength of the parts manufactured by this process using both  and s charts.Samples of size 9 are to be taken at regular intervals,and their mean compressive strength (in psi = pounds per square inch) and standard deviation are plotted on the charts in time order.The target values for the compressive strengths are a mean of = 80 psi and a standard deviation of = 3 psi.The control chart constants are (partially) reproduced below.

and s charts.Samples of size 9 are to be taken at regular intervals,and their mean compressive strength (in psi = pounds per square inch) and standard deviation are plotted on the charts in time order.The target values for the compressive strengths are a mean of = 80 psi and a standard deviation of = 3 psi.The control chart constants are (partially) reproduced below.  Suppose at the time of sample 10,we observe a mean of 85 psi.What should we do?

Suppose at the time of sample 10,we observe a mean of 85 psi.What should we do?

A) Declare the process out of control.

B) Continue sampling-the process is still in control.

C) Continue sampling,but increase the sample size to 16.The process is barely in control.

D) Continue sampling,but reduce the sample size to 4.The process is well in control.

Correct Answer:

Verified

Correct Answer:

Verified

Q66: Parts manufactured by an injection molding process

Q67: What is the main function of a

Q68: The data below represent the means from

Q69: The sampling distribution of <img src="https://d2lvgg3v3hfg70.cloudfront.net/TB5065/.jpg" alt="The

Q70: At the start of the semester,a professor

Q72: An automobile dealer checks on the quality

Q73: Out of control signals are produced from

Q74: The capability index <img src="https://d2lvgg3v3hfg70.cloudfront.net/TB5065/.jpg" alt="The capability

Q75: Suppose you are the owner of a

Q76: You have been invited to give a