Multiple Choice

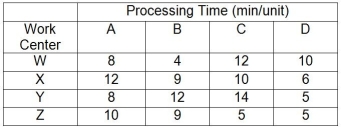

Table 7.7

A company makes four products that have the following characteristics: Product A sells for $75 but needs $20 of materials and $20 of labor to produce;Product B sells for $90 but needs $45 of materials and $20 of labor to produce;Product C sells for $110 but needs $50 of materials and $30 of labor to produce;Product D sells for $135 but needs $75 of materials and $40 of labor to produce.The processing requirements for each product on each of the four machines are shown in the table.  Work centers W,X,Y,and Z are available for 40 hours per week and have no setup time when switching between products.Market demand is 50 As,60 Bs,70 Cs,and 80 Ds per week.In the questions that follow,the traditional method refers to maximizing the contribution margin per unit for each product,and the bottleneck method refers to maximizing the contribution margin per minute at the bottleneck for each product.

Work centers W,X,Y,and Z are available for 40 hours per week and have no setup time when switching between products.Market demand is 50 As,60 Bs,70 Cs,and 80 Ds per week.In the questions that follow,the traditional method refers to maximizing the contribution margin per unit for each product,and the bottleneck method refers to maximizing the contribution margin per minute at the bottleneck for each product.

-Use the information in Table 7.7.Using the traditional method,in what sequence should products be scheduled for production?

A) A,B,C,D

B) A,C,B,D

C) A,D,B,C

D) D,B,C,A

Correct Answer:

Verified

Correct Answer:

Verified

Q1: Table 7.7<br>A company makes four products that

Q3: Figure 7.1 <img src="https://d2lvgg3v3hfg70.cloudfront.net/TB2904/.jpg" alt="Figure 7.1

Q4: Table 7.15<br>The Terminal Company is attempting to

Q4: How can Theory of Constraints principles be

Q5: Table 7.12<br>A company desires to set up

Q6: The movement of product from one station

Q7: Table 7.12<br>A company desires to set up

Q8: Table 7.14<br>The production of a particular product

Q13: The process batch at the constraint in

Q92: A line balance that is 100% efficient