Multiple Choice

Table 7.8

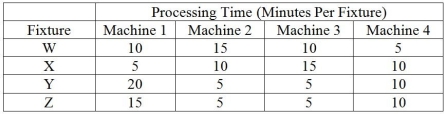

King Supply makes four different types of plumbing fixtures: W,X,Y and Z.The contribution margins for these products are: $70 for Product W,$60 for Product X,$90 for Product Y and $100 for Product Z.Fixed overhead is estimated at $5,500 per week.The manufacture of each fixture requires four machines,Machines #1,2,3 and 4.Each of the machines is available for 40 hours a week and there is no setup time required when shifting from the production of one product to any other.The processing requirements to make one unit of each product are shown in the table.Weekly product demand for the next planning period has been forecasted as follows: 70 Ws,60 Xs,50 Ys and 30 Zs.  In the questions that follow,the traditional method refers to maximizing the contribution margin per unit for each product,and the bottleneck method refers to maximizing the contribution margin per minute at the bottleneck for each product.

In the questions that follow,the traditional method refers to maximizing the contribution margin per unit for each product,and the bottleneck method refers to maximizing the contribution margin per minute at the bottleneck for each product.

-Use the information in Table 7.8.Using the traditional method,in what sequence should the fixtures be scheduled for production?

A) Z,Y,X,W

B) X,W,Z,Y

C) Z,Y,W,X

D) W,X,Y,Z

Correct Answer:

Verified

Correct Answer:

Verified

Q22: Explain why a bottleneck limits system output.

Q87: The Theory of Constraints method is also

Q125: Immediate predecessors are the smallest units of

Q126: A line-balancing solution has been developed for

Q127: Table 7.6<br>Burdell Industries makes four different models

Q130: Table 7.5<br>A company makes four products that

Q131: Table 7.8<br>King Supply makes four different types

Q132: Table 7.8<br>King Supply makes four different types

Q133: Table 7.5<br>A company makes four products that

Q134: Table 7.2 <img src="https://d2lvgg3v3hfg70.cloudfront.net/TB2904/.jpg" alt="Table 7.2