Multiple Choice

Table 5.2

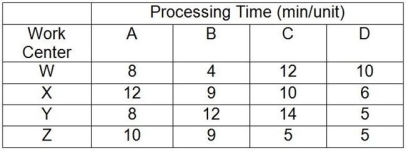

A company makes four products that have the following characteristics: Product A sells for $75 but needs $20 of materials and $20 of labor to produce; Product B sells for $90 but needs $45 of materials and $20 of labor to produce; Product C sells for $110 but needs $50 of materials and $30 of labor to produce; Product D sells for $135 but needs $75 of materials and $40 of labor to produce. The processing requirements for each product on each of the four machines are shown in the table.

Work centers W, X, Y, and Z are available for 40 hours per week and have no setup time when switching between products. Market demand is 50 As, 60 Bs, 70 Cs, and 80 Ds per week. In the questions that follow, the traditional method refers to maximizing the contribution margin per unit for each product, and the bottleneck method refers to maximizing the contribution margin per minute at the bottleneck for each product.

-Use the information in Table 5.2. Using the traditional method, in what sequence should products be scheduled for production?

A) A, B, C, D

B) A, C, B, D

C) A, D, B, C

D) D, B, C, A

Correct Answer:

Verified

Correct Answer:

Verified

Q18: A competent operations manager should first eliminate

Q19: Line balancing is the assignment of work

Q20: Which statement about process batches is best?<br>A)

Q21: The focus for a process improvement exercise

Q22: Explain why a bottleneck limits system output.

Q24: Table 5.4<br>The Superior Management Company assembles muffalettas

Q25: Table 5.1<br>A company makes four products that

Q26: Table 5.3<br>King Supply makes four different types

Q27: Consider the following production process. It is

Q28: Which of the following statements concerning line