Essay

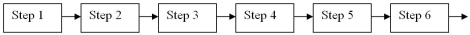

Consider the following production process.It is trying to meet a market demand of 500 units per week.  Step 1: Material release schedule

Step 1: Material release schedule

Step 2: Drilling (capacity is 500 units/week)

Step 3: Tapping (capacity is 450 units/week)

Step 4: Grinding (capacity is 600 units/week)

Step 5: Coating (capacity is 400 units/week)

Step 6: Inspection (capacity is 1000 units/week)

a.Where should buffers be placed?

b.Which resource is the drum?

c.Where should the rope be placed?

d.Which resource is the bottleneck?

e.Which resource is the CCR?

Correct Answer:

Verified

a.A constraint buffer should be placed b...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q10: Describe three ways that line balancing and

Q12: The production of a particular product consists

Q14: Schmidt Industries makes four different snake traps;the

Q18: Which of the following statements concerning line

Q31: Regardless of the number of tasks or

Q42: Short term capacity planning should be driven

Q56: Variability of a firm's workload may create

Q59: In a drum-buffer-rope system, the lot size

Q131: What is the definition of "theoretical maximum

Q135: Table 5.1<br>A company makes four products that