Essay

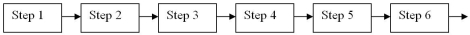

Consider the following production process.It is trying to meet a market demand of 250 units per week.  Step 1: Material release schedule

Step 1: Material release schedule

Step 2: Drilling (capacity is 300 units/week)

Step 3: Tapping (capacity is 150 units/week)

Step 4: Grinding (capacity is 300 units/week)

Step 5: Coating (capacity is 200 units/week)

Step 6: Inspection (capacity is 500 units/week)

a.Where should buffers be placed?

b.Which resource is the drum?

c.Where should the rope be placed?

d.Which resource is the bottleneck?

e.Which resource is the CCR?

Correct Answer:

Verified

a.A constraint buffer should be placed b...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q21: The focus for a process improvement exercise

Q23: Table 5.2<br>A company makes four products that

Q29: To generate the maximum output, the cycle

Q34: Table 5.4<br>The Superior Management Company assembles muffalettas

Q89: Table 5.3<br>King Supply makes four different types

Q90: Figure 5.1<br> <img src="https://d2lvgg3v3hfg70.cloudfront.net/TB1252/.jpg" alt="Figure 5.1

Q102: Figure 5.3<br> <img src="https://d2lvgg3v3hfg70.cloudfront.net/TB1252/.jpg" alt="Figure 5.3

Q123: Describe a process from your own personal

Q127: Table 5.1<br>A company makes four products that

Q132: Table 5.4<br>The Superior Management Company assembles muffalettas