Essay

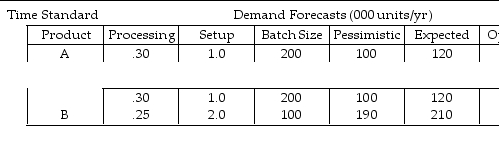

Larry's Wickets, Inc. is producing two types of products: A and B. Both are produced at the same machining operation. Because of demand uncertainties, the operations manager obtained three demand forecasts (pessimistic, expected, and optimistic). The demand forecasts, batch sizes (units/batch), processing times (hr/unit), and setup times (hr/batch) follow.

The machines operate on two 8- hour shifts, 5 days per week, and 50 weeks per year. The manager wants to maintain a 20 percent capacity cushion.

a. What is the minimum number of hours required of the machining equipment for the next year?

b. How many hours of capacity can the company expect from each machine?

c. What is the minimum number of machines needed (assuming no reliance on short- term options)?

d. What is the maximum number of machines needed (assuming no reliance on short- term options)?

Correct Answer:

Verified

Scenarios that can be met wi...View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Correct Answer:

Verified

Scenarios that can be met wi...

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q91: Give four principal reasons why economies of

Q92: The maximum output that can reasonably be

Q93: Many alternative strategies are available for the

Q94: If a system is well balanced, which

Q95: Musk L. Flexor owns a hot tub

Q97: Table 5.2<br>High Tech, Inc. is producing two

Q98: Diseconomies of scale refers to situations where

Q99: Which one of the following statements about

Q100: The _ time for a specific item

Q101: Describe the fundamental logic of the theory